Our tailoring workshop is composed of several poles ranging from the reception of knitting to the expedition of the finished product:

Our tailoring workshop cuts by hand, following the patterns provided by the standardization-gradation team.

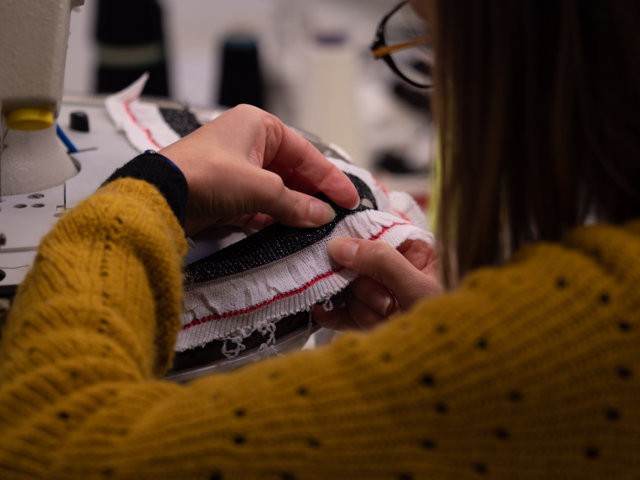

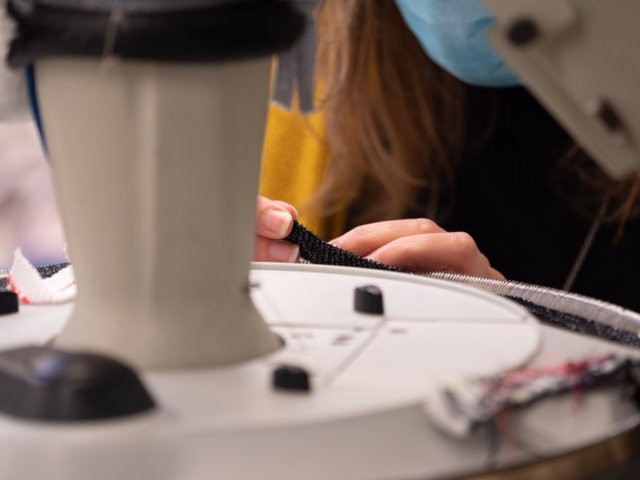

We work in groups of 3 to 5 assembly operators. Each group assembles the complete product thanks to the versatility of the teams and various assembly machines: flat machines, linking machines, overlocker machines, special embellishment machines, …

The finishing team carries out the work by hand: pulling in loose threads, crochet, hand knitting, shaving, thread cutting, buttonholes, buttons, hooks, snaps, …

Each product goes through quality control to control compliance with the specifications

Repairing requires mastery and a great understanding of knit stitches; it consists in retrieving the stitches that have broken during knitting by following the various patterns and stitches.

This is the last control point before packing, we can check the measurements and the development of the garment (if necessary on dummy)

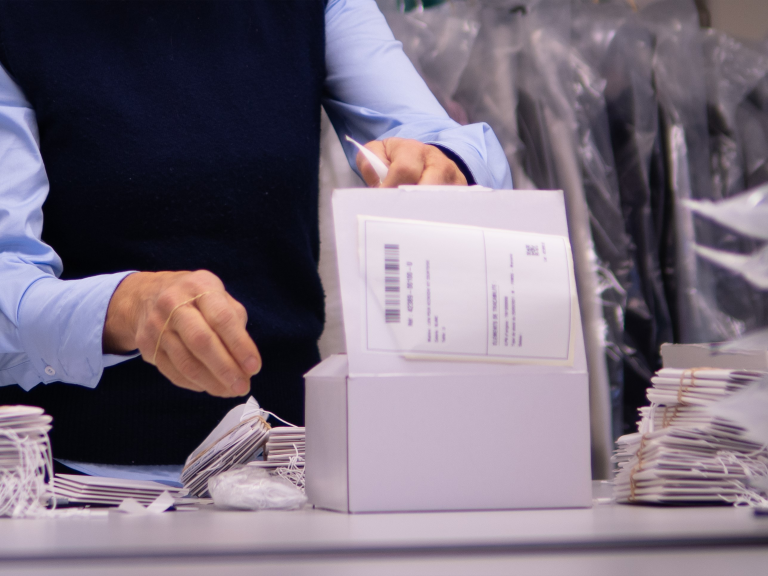

Your products are packaged according to your specifications, we affix the desired identifications (for example a QR-code). We ship as standard or express or make the products available to your own carrier. The delivery note can be sent to you by email the same day.

Also discover

As a company geared towards innovation, the design office is at the heart of development.

Maille Création is equipped with a large and diversified machine park allowing it to always better adapt to the most demanding requests.

Our team of pattern-graders manages the standardization models for production.

Are you looking for a partner to develop your high-end knitwear collection?

Would you like to join us?

Would you like to entrust us with the production of knitted pieces (ready-to-wear, haute couture, or other)?